google-site-verification=090LuFlx38lrYGF_tjZmK6RpOe9c0QMFo-4lVQ9Cl5U

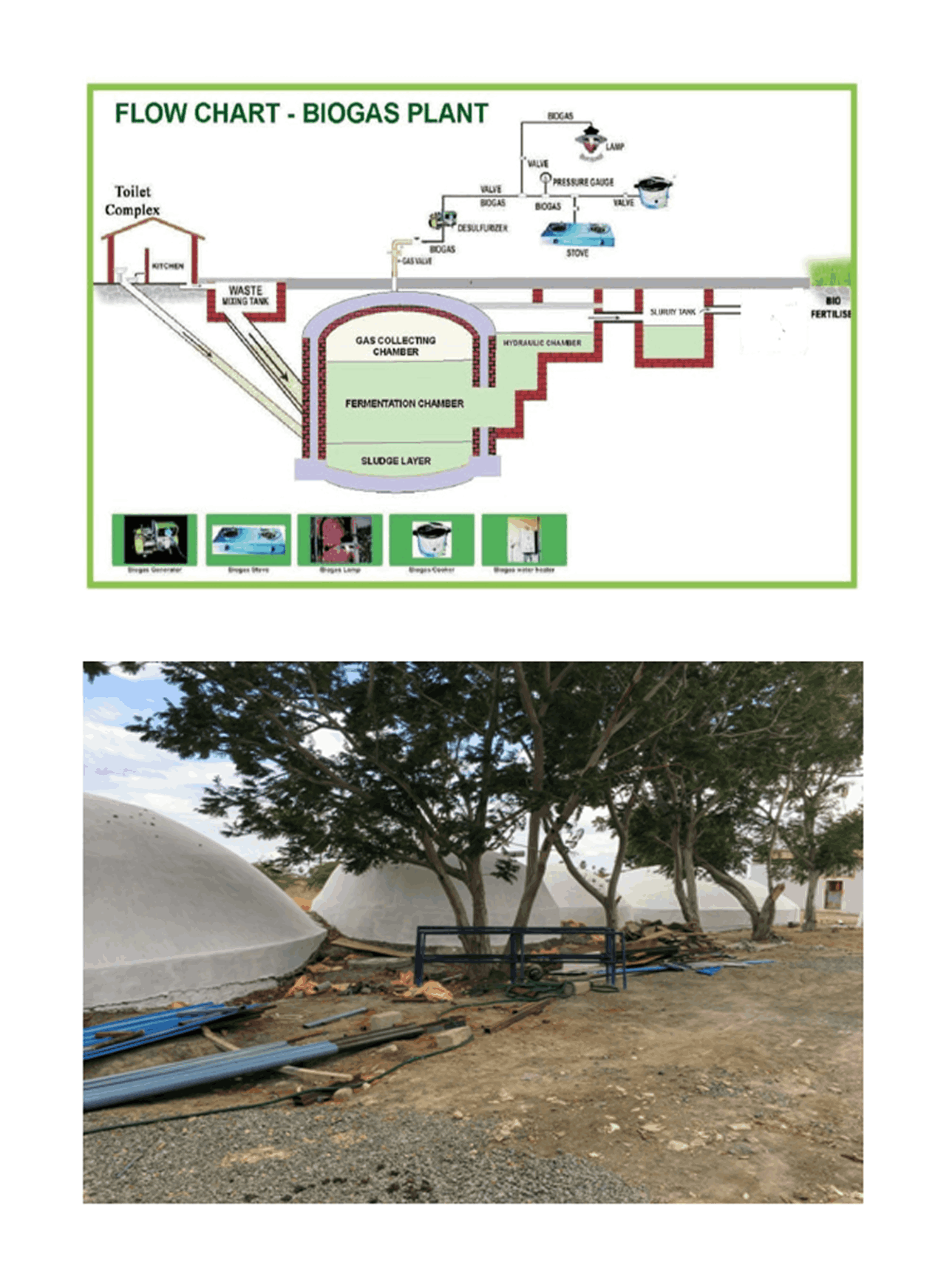

Biogas is a mixture of colourless and odourless gases. Biogas can be produced through fermentation from any degradable material (Substrate) with the help of different types of tiny microbes. It can be produced in a concealed chamber/ digester in the absence of atmospheric oxygen. Biogas is a mixture of different gases, major portion in biogas being methane (CH4) and carbon dioxide (CO2). It also contains traces of other gases like hydrogen (H2), Moisture (H2O) , hydrogen sulphide (H2S)etc.

The biogas can be used for different thermal applications like cooking, lighting, operating engines, generation of electricity and for making auto fuel.. Biogas can be purified and upgraded in accordance with the standards of natural gas. The upgraded / Compressed Bio Gas can be used for running vehicles and other applications including different industrial needs

Waste of food materials, human excreta and other bio degradable wastes generated in Factory canteens, Convents, Hospitals, Hostels, Hotels, Convention centers, apartments and other industrial organizations can be treated in an eco-friendly way for the production of cooking gas in very large scale.

The organic waste generated from public institutions like Market and slaughter houses etc can be used for the generation of electricity through the installation of treatment plants. *1.5 KW electricity can be produced from one cubic meter of biogas.

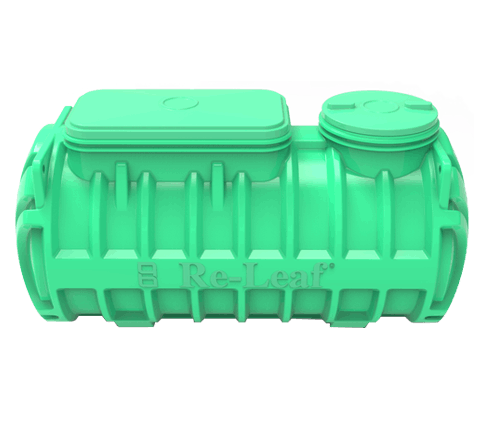

• Accelerate digestion/degradation process by

10 times, compared to a normal septic tank.

• Decomposition happens in 3-4 days as

compared to normal septic tank which takes

approximately 40 days

• No methanogens in the consortium hence less

greenhouse gases.

• Wide range of ambient operating temperature.

• 95% organic sludge degradation within 72 hours of retention

• Reduced contamination in discharge water

• No requirement for scavenging/emptying

under normal operating condition.

• Scalable and sustainable.

• Provision for water reuse.

• Sturdy and rigid tank design

• A maintenance-friendly design that permits easy

inspection chambers compared to the normal

septic tank.

• 100% virgin material to ensure long life &

recyclability, thereby ensuring reduced impact

to the environment.

Use Mobirise website building software to create multiple sites for commercial and non-profit projects.

MODEL AA20: 20-25 flushes/daily

MODEL AA30: 30-40 flushes/daily

MODEL AA45: 45-55 flushes/daily

Model B 3000: 65 flushes/day

Model B 5000 : 100 flushes / day

Model B 10000 : 200 flushes/day

Model B 20000: 400 flushes/day

Higher capacity tanks can be custom made as per requirements. Efficient filtration and recycling modules are also manufactured and supplied as per requirements.

'Rainy' Dual Intensity filters work at high efficiency regardless of the intensity of rainfall and have self-cleaning abilities. At nominal prices, our filters are market leaders in Rooftop Rain Water Harvesting.

Some of our major clients….

.Majmau ssaquafathil Islamiyya,Nilamboor,Kerala.

• Darul Irshad Educational

Centre,Bantwala,Karnataka.

• AWH engineering college,calicut

• MAFM orphanage,Padijatemuri,Malappuram

• AWH special college,Calicut

• Al Ifsan English medium school,Vengara,

Malappuram

• Rahmania HSS, calicut

• MIC Darul Irshad Acadamy,uduma,Kasaragod

• Islahiya Association, Chendamangalore,Calicut

• Al shifa Nursing college,Perinthalmanna,

Malappuram

• Moulana Nursing College,Perinthalmanna,

Malappuram

• Darussalam Arabic college,Nandi,Calicut

• IISER, Trivandrum

• KMCT polytechnic,Kalanthod,Calicut

• Rahmania Orphanage,Olavilam,Kannur

• Ahalya Hospital,Palakkad

• Viveka Hospital, Calicut

• St. Josephs Hospital, Rampur, UP

• Malappuram dist. Co op Hospital,Malappuram

• Al Salama Hospital, Vengara, Malappuram

• Meditrna super specialty Hospital,Kollam

• Moulana Hospital, Perinthalmanna,Malappuram

• Moulana de addiction centre,Perinthalmanna,

Malappuram

• Aster Medcity, south chittoor, Kochi

• Al shifa Hospital, Perinthalmanna,Malappuram

• Metro cardiac hospital,Calicut

• Manassanthi Hospital,kaithkundu,Malappuram

• Hotel Hyson, Calicut

• Asma Tower, Calicut

• Nakshatra regency, Koppam,Palakkad

• Hotel Kingsbay, Calicut

• KTDC Hotel, Changanasseri

• KTDC Hotel Kumarakom, Kottayam

• KTDC Hotel, Guruvayoor

• M sons residency, Calicut

• The Oven restaurant, Calicut

• Chicking, Calicut

• Hotel Wayand Gate, Lakkidi, Wayanad

• Nirmalya residency,Changaramkulam

• Light house restaurant,Calicut

• Shalimar residency,Koyilandy,Kozhikode

• Ahammed Roller Flour Mills(P)Ltd,Calicut,

Kerala.

• Peekay Rolling Mills(P)Ltd,Calicut, Kerala.

• Parison Agrotech (P)Ltd,Calicut, Kerala.

• Parison Foods,Kakanjeri,Malappuram

• Yen key flour mill,Calicut

• Parison Agrotech (P)Ltd,Moovatupuzha,Kerala.

• Khemka Flour Mill,Calicut

• Parisons,Angamali,Eranakulam

• Malabar Gold,Calicut

• Nalakath Granites,Perinthalmanna,Malappuram,

Kerala

• Steel max,Knjikode,Palakad

• Special Armed Police,Oolampara,Trivandrum

• PVR Village,Manjeri,malappuram

• Athafy Auditorium,Vatakara,Calicut

• Krishnakripa kalyanamandapam,Vatakara,Calicut

• Oceanus,Harmony,Kasaragod

• Seashore Auditorium,Parappil,Calicut

• Oceanus Crescent,Kalady,Eranakulam

• Oceanus Maple,Edapally,Kochi

• Kreeno recidency,Calicut

• Oceanus Spandana,Kannoor

. ULCC,Vatakara,Calicut

• Metro hospital, Calicut

. Oceanus Regal, Trivandrum

. Kailas apartment,Calicut

. Blue marine Mall,Payyannur

. Oceanus green valley,Trivandrum

. Udupi Municipal,Market,Udupi,Karnataka

. Kannur International Airport Ltd

. Cochin Special Economic Zone

. Keerthana homes,Palakad

. Oceanus Marvel,Iritty Kannur

. Markaz farm,puthupadi, Calicut

. Hilite city,Calicut

. Jewel 3 apartments, Palakad

. Water transport department,Alapuzha

. MRA,Kannur

. Down town,Calicut

. Club Mahindra,Kumily,Idukki

. NPM Aqautic fish links (P) Ltd, Perumbilavu,

Thrissur

. Hotel royal plaza, Calicut

• Community hall, Shmoga, Karnataka

• E3 Theme park, Wayanad,Kerala

• Sri Narayana Institute of Medical science ,

Eranakulam

• KTDC Veli, Trivandrum,Kerala,

• KTDC Kottarakara,Kerala

• Rainbow Mall,Chalode,Kannur,Kerala

• Steel max, Palakkad, Kerala

• Pearl city, Tticorin, Tamilnadu

• Avitis Hospital,Nenmara, Palakkad, Kerala

• White school, Calicut

• Adlux Hospital, ankamali, Kerala

• Rjagiri school of engineering,Eranakulam, Kerala

• Kiwi ice cream, Palakkad,Kerala

• Ghazal Builders,Wayanad,Kerala

• Co-op Hospital,Kumbala,Kasaragod, Kerala

• Peace village,Wayanad,Kerala

• Chinmaya vidyalaya, Calicut, Kerala

• Aater Mims, Kannur, Kerala

• Sreerosh Builders, Kannur, Kerala

• Federalgreens apartments, Aluva, Kerala

• BEM school, Calicut, Kerala

• IIIC, Chavara, Kollam, Kerala

• Sobha developers, Calicut, Kerala

• Thejwasini hospital, NEELESWARAM,Kasaragod,

Kerala

• Pig farm, Perumdurai, Erode, Tamilnadu

• OPH convetion center, Amayur, Palakkad, Kerala

• ULCC labor camp, RCC, Trivandrum, Kerala

• Care home, Medical college, Calicut, Kerala

• Fezz inn Hotels,Markaz knowledge city,

Kaithapoyil, Kozhikode, Kerala

• Ladder Hotels n resorts , S Batheri, Kerala

• NPM associates, Tuticorin, Tamilnadu

• Sanjari Marine products, sayalkudi, Tamilnadu

• Wafy college, Chokli, Kannur, Kerala

• Co-Op Hospital, Cherpulasseri, Palakkad, Kerala

• Ayurevoir Resorts, malampuzha, Palakkad, Kerala

• Tigris Valley, Markaz Knowledge city,Kaithapoyil,

Kozhikkode,Kerala

• Marksmen Marine products pvt Ltd, Kochi,

Kerala

• Nahala Hotels and resorts,

Kalpetta,Wyanad,Kerala

• Marksmen Aquatics Products LLP, Tuticorin,

Tamilnad

• Westcade Hotels, Kalpetta, Wayanad, Kerala

• Holly Cross College, Calicut, Kerala

• Hilite Business Center, Calicut, Kerala

• NPM marine products, Oman

• Taluk Hospital, Perinthalamanna,Malappuram

• Unnikulam grama panchayath,Kozhikode

• Govt. District Hospital, Manjeri,Malappuram

• CHC Balusseri,Kozhikode

• Kunnamangalam grama panchayath,Kozhikode

• Shornur Municipality

• Pre metric Hostel,Shornur

• Taluk Hospital, Nilamboor,Malappuram

• CHC Thamarasseri,Kozhikode

• Govt. District Hospital,Idukki

Designed with

Mobirise